Laboratoire d’Étude

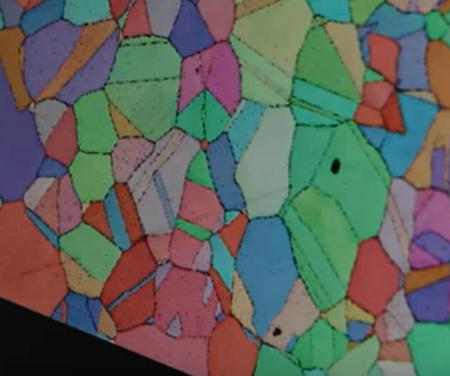

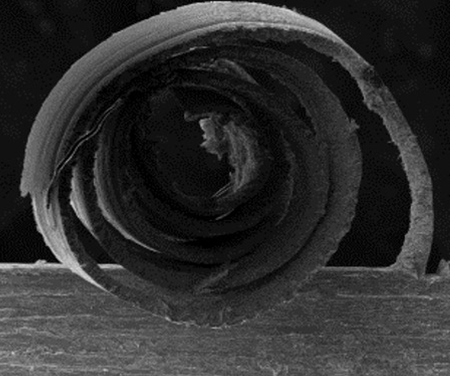

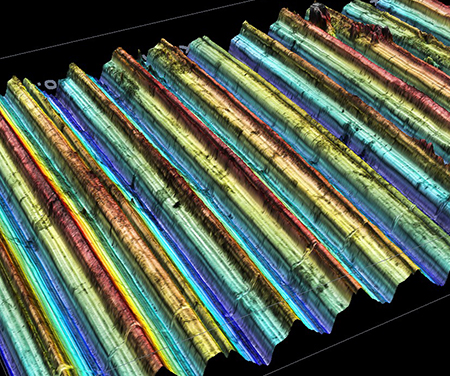

des Microstructures

et de Mécanique

des Matériaux

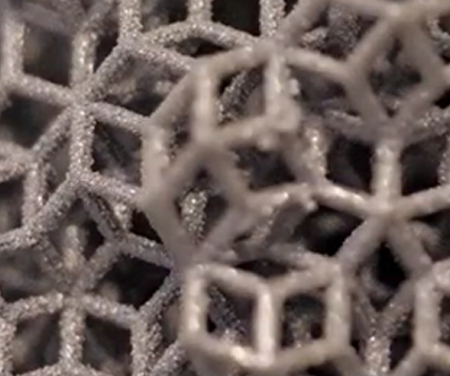

Le LEM3 est un laboratoire de recherche fondamentale et appliquée dans le domaine des Matériaux, la Mécanique et les Procédés.

C’est une unité Mixte de Recherche CNRS – Université de Lorraine – Arts et Métiers regroupant 250 personnes.

Nos travaux de recherche ont l’ambition de contribuer aux grands défis sociétaux en matière de santé, de transition énergétique et numérique.

ACTUALITÉS

PUBLICATIONS

AGENDA

25 Avr 2024

Séminaire

Julien Yvonnet : Méthodes de « clustering » pour l’accélération des simulations multi échelles non linéaires dépendants du trajet de chargementSalle de réunion du 1e étage, LEM3 – site principal, 7 rue Félix Savart, 57070 Metz

10 Mai 2024

10 Mai 2024

Vie du laboratoire

Fermeture LEM3 (pont de l’Ascension 2024)LEM3 – site principal, 7 rue Félix Savart, 57070 Metz

14 Mai 2024

Médiation scientifique

Pint of Science 2024 – IA et entropie au service de la mémoire des métaux !La Douche Froide, 11 rue des Augustins, 57000 Metz

le lem3 en chiffres

250

PERSONNES

70

DOCTORANTS

50

PROJETS DE RECHERCHE EN COURS

80

COLLABORATIONS

INTERNATIONALES

150

PUBLICATIONS

PAR AN

3

PLATEFORMES TECHNOLOGIQUES